Performance at its very best

-

CapacityThe capacity of the Javo Toploader is up to 25 cubic meters per hour (depending on model).

-

High efficiencyThe Javo Toploader uses 100% of the material.

No waste material will be left. -

Minimal lossThere is minimal loss of storage capacity, because the bunker can be loaded very efficiently inside its own rail system.

-

CommunicationThe Javo Toploader is in continuous communication with its operator, your material supplier and even our engineers.

-

Low energy consumptionThe Javo Toploader is extremely efficient and consumes little energy.

-

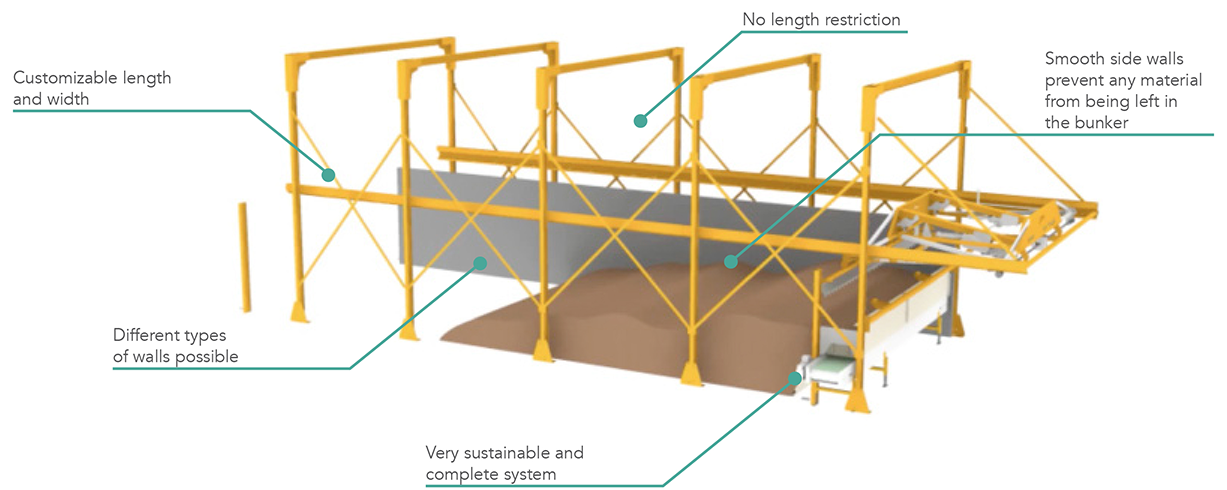

Adjustable dimensionsThe Javo Toploader can be customized to virtually any width or length, depending on requirements and capacity.

-

Suitable for any materialAlmost every kind of bulk material can be placed inside the Javo Toploader, including wood chips, sand and waste material.

-

Unique stacking programThe software allows for real-time remote monitoring and no wasted motion as it moves material.

BENEFITS OF THE TOPLOADER

-

GROUND LEVELThe Toploader is built at ground level so there is no need for underground work. Means no issues with ground water and a very simple installation.

-

COST-EFFECTIVENo need for expensive concrete construction allowing a rapid and low-cost installation.

-

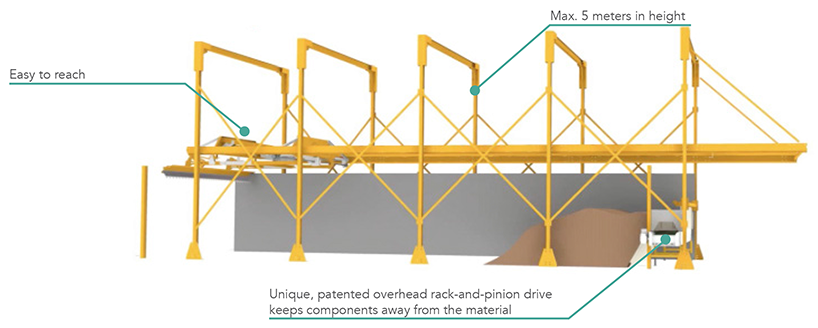

EASY ACCESThe moving parts are located above the biomass, which gives easy access to the Toploader for maintenance etc.

-

LOW ENERGYOnly driven by two 2,2 kW electric motors instead of ‘heavy’ hydraulic packs and cylinders.

-

LOW MAINTENANCE COSTSAlmost all the maintenance can be done by the operator leading to low maintenance costs. The minimum wear of parts further reduces maintenance costs.

-

MANAGEMENTThe Toploader touchscreen supplies useful information concerning the operation, the stock, almost empty signal, etc. This leaves you fully in control of the heating process. The system makes adjustments possible in all these features, improving the management possibilities of the whole heating process.

-

EASY TO CONNECTThe Toploader can easily be connected with a ‘home’ PC to receive operating information, allowing easy management from off site.

-

BIG STORAGE CAPACITYDifferent widths and flexible lengths, two or more Toploaders next to each other. This makes a big storage capacity possible, as much as 3.000 m3 if required.

-

PORTAL FRAMEThe structure of the portal frame version not only provides cost-effective walls, but also enables a roof structure to be easily attached, protecting the energy in your fuel.

-

Fuel Reception, Storage and Recovery all in one!

The Javo Toploader definitely works for you

-

The bunker can be loaded very efficiently inside its own rail system, which ensures minimum loss of storage capacity.

-

Once that is done, and the area is secured, the system comes out and looks across the heap with a sonar to see how much material is in the hopper.

-

Then it will start automatically moving the material to the front of the hopper. The patented scraping technique delivers the bulk material to a discharge conveyor.

-

The fork is powered back and forth automatically and a smooth side wall of the machine prevent any remaining substrate remaining in the bunker. The spindle track and guide frame are constructed in combination and can be mounted to existing construction.

-

It is always looking to maximize the storage area in the bunker as well. The Toploader is in continuous communication with its media necessities.

-

The touch screen display shows the capacity in the hopper and how much is free and how much is full.

-

All movements are PLC controlled and equipped with electronic speed control. All moving and electrical parts are mounted away from the bulk material, which makes it easy to reach for maintenance.

From technical point of view;

it’s always about details

-

Suitable for any materialAlmost every kind of bulk material can be placed inside the Javo Toploader, for example wood chips, bark and other biomass, agricultural and (waste) bulk material.

-

LengthNo length restriction.

-

Width4, 5 or 6 meters

-

Height materialmax. 1,9 meters (Slim Line) up to max. 4 meters (Industrial Line)

-

CapacityThe feed capacity of the Javo Toploader is up to 25m2 per hour (depending on model)

-

WeightDepends on the model.

-

Voltage400V 50Hz / 220V 60Hz.

-

Power4kW (Slim Line), 5,5kW (Industrial Line)

-

Power connection16A, 5 pole, CEE outlet (Slim Line), 32A, 5 pole, CEE outlet (Industrial Line)

We are all connected

The cooperation between the different companies in the Nobels Group is decades old. These companies combine to produce the most innovative solutions available for automation and robotics in the agricultural, horticultural and industrial markers.

www.nobels-group.com

Nobels machinefabriek bv was founded in December 1955, by Mr. Arnold Van Nobelen.

He started to develop a sorting machine for the agricultural industry from a 300 m2 greenhouse in Holland. Nobels produced the first prototypes of the planting and lifting machines in 1958. Three years after that, the greenhouse was getting too small and Nobels moved to a new building in the same village.

It was at this time that Javo and Nobels began to work together, extending their production lines with agricultural and horticultural machinery. Nobels moved two more times, in 1975 and 1986, and is located in Katwijk, Holland. The factory has grown to 11,000 m2 and Javo BV was purchased by Nobels in 2000.

Javo BV was founded in December 1947. The name JaVo is an abbreviation derived from the name of the founder: Jacques Vonk.

Javo was a limited liability company until 1972, but in December of that year it became a private company. Although involved in other business pursuits, Javo was originally an export company dealing mainly in the exportation of fruits and vegetables.

In 1966 Javo moved to Noordwijkerhout where it first settled in the Zeestraat; the following year, Javo produced its first machines. At this time the company became listed as a wholesale company, also involved in the import and export of horticultural machines. Because of its continued growth, Javo moved two more times within Noordwijkerhout before finally settling at the Westeinde.

Currently Javo is the market leader in the area of potting and re-potting machines, robotic systems, and pot handling automation for the pro- duction and handling of potted plants, bedding plants and nursery stock.

Agro Techniek Holland BV was founded in 1959, to be a company for the flower bulb branch. They produce and sell quality machinery to customers all over the world, built in their own factory and at Nobels machinefabriek bv.

The program contains quality (trademark) machinery from New Holland, Nobels, Kawasaki and other machinery for the worldwide agriculture industry. Agro Techniek Holland also produces its own special ATH machinery that fits the needs of their agricultural customers.

The cooperation with Nobels goes back to the start of Agro Techniek Holland, but the company is part of the Jano Holding since 2014.

The Javo Toploader has been a

well known machine in the Javo BV program for 15 years. But the system is also very successful in other branches than horticulture.

That is why Javo International was founded in 2014, to focus on this machine for the worldwide markets. Together with the expertise of Javo BV and Nobels machinefabriek, the proven Javo Toploader is now successfully operating for the transportation of biomass and other bulk material.

We at Javo International can provide our customers with excellent advice and customized solutions to specific problems. Javo provides

a first class after sales service. We have installed over 60 Javo Toploaders worldwide.

Your sales agent will contact you as soon as possible.